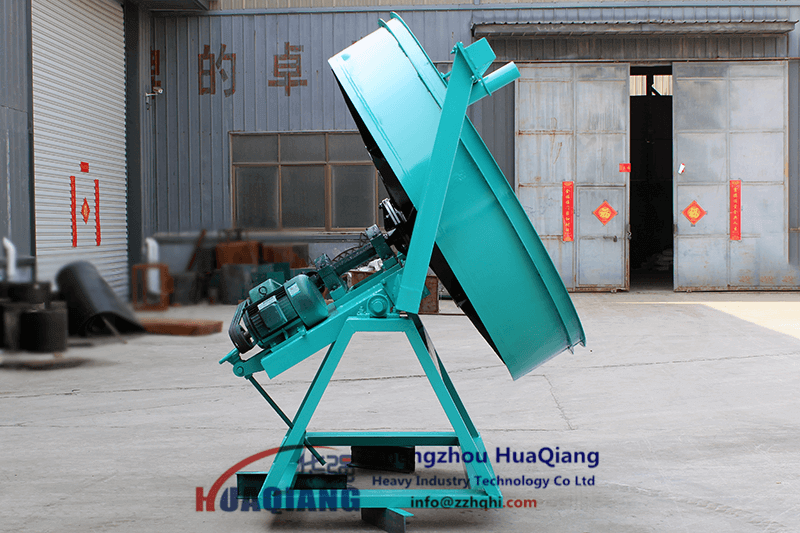

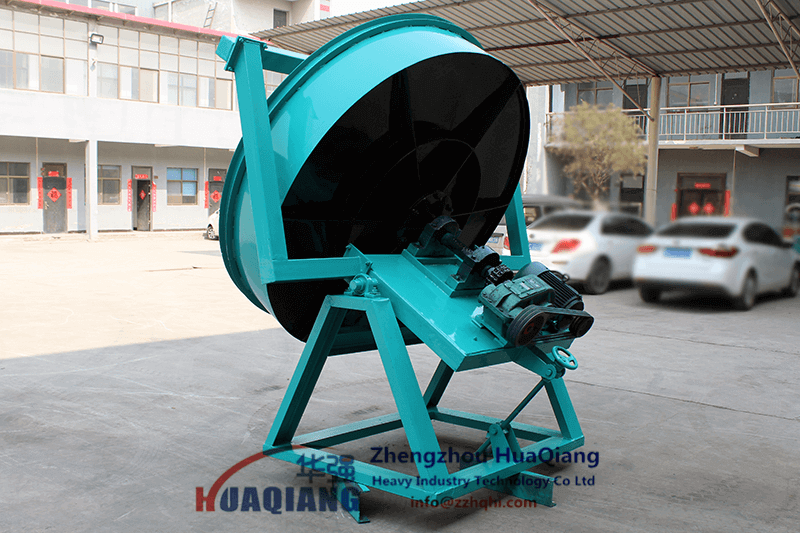

Features

1. Overall disc structure, granulation rate reaches above 93%.

2. The design of granulation plate is convenient for intermittent continuous production, which greatly reduces the labor intensity and improves labor efficiency.

3. The reduction gears and motor using the flexible belt driving, smooth start, slowing impact, extend equipment service life.

4. The disc bottom adopts multiple steel plates which are firm, durable, not deforming.

5. The design of disc bottom is thicker, heavier and more stable, not need to be fixed by anchor bolts.

6. Granulator’s main gears adopt high temperature quenching technology, doubling the service life.

7. The granulator’s disc lining adopts the high strength glass steel which is antiseptic and durable.

8. The granulator is with the high uniform granulation, high granulation rate, long service life, which is an ideal equipment for majority of users.

Specification

| Model | Inner diameter (mm) | Side height (mm) | Volume(m³) | Rotation speed (r/min) | Motor power(KW) | Production Capacity (T/h) | Decelerators model |

| ZL10 | 1000 | 250 | 0.4 | 24 | 2.2 | 0.3-0.5 | XW5-59 |

| ZL15 | 1500 | 300 | 1.1 | 22 | 5.5 | 0.5-0.8 | ZQ250-48 |

| ZL18 | 1800 | 300 | 1.4 | 18 | 5.5 | 0.6-1.0 | ZQ250-48 |

| ZL20 | 2000 | 350 | 1.8 | 18 | 7.5 | 0.8-1.2 | ZQ250-48 |

| ZL25 | 2500 | 350 | 2.5 | 18 | 7.5 | 1.0-1.5 | ZQ400-23 |

| ZL28 | 2800 | 400 | 3.3 | 18 | 11 | 1.0-2.5 | ZQ400-48 |

| ZL30 | 3000 | 450 | 3.9 | 16 | 11 | 2.0-3.0 | ZQ350-23 |

| ZL32 | 3200 | 500 | 4.3 | 13.6 | 15 | 2.0-3.5 | ZQ350-23 |

| ZL36 | 3600 | 550 | 5.5 | 11.3 | 18.5 | 3.0-5.0 | ZQ400-23 |

| ZL45 | 4500 | 600 | 6.5 | 8 | 22 | 4.0-6.0 | ZQ250-48 |